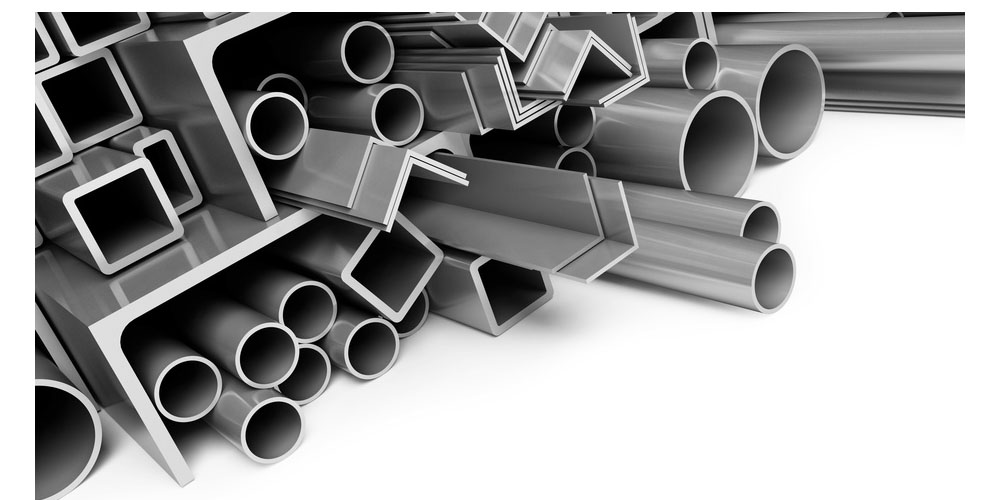

Metal extrusion refers to a viable manufacturing process where a billet in a cylindrical shape is in a closed cavity. The billet is then forced to flow into a die cross-section. The cross-sectional profile will then play the role of extruding a mechanical, hydraulic press.

Primary materials used in metal extrusion

When Joseph Bramah patented the processes of metal extrusions, he strictly extruded lead pipes. What started as a mechanical experiment is currently used to shape metals. Some of the materials used include copper, magnesium, ceramics, and lead.

Factors affecting the quality of metal extrusion

One of the crucial elements affecting the quality and productivity in metal extrusion is complexity in shape. This is an estimation of the complexity of an extruded profile. Besides, it has a direct bearing on the equipment selection, die, tooling design, coupled with energy consumption, among others.

The complexities of the extruded materials

In turn, the material complexities have a significant impact on different materials affecting dyeing and metal extrusions. Without an appropriate quantification of various shapes and complexities, it is challenging to tell the maximum extrusion pressure required by a manufacturer to optimize the process of dying.

Top traits of metal extrusion processes

Metal extrusion plays a significant role in creating various cross-sections in engineering and design. These cross-sections should be uniform over some time.

A few elements that may end up affecting your extrusion process include the billet temperature, lubrication, in addition to the speed involved. To comprehend the design variables of the metal extrusion, you need to learn the following design tips:

Like other metal forming processes, extrusion can easily be performed cold or hot. Even so, the process is carried out at a variety of elevated temperatures. This is to cut down the extrusion force. While at it, the process plays an instrumental role in improving the material’s ductility.

- Low cost because of the reduced wastage of raw materials.

- High production rate and quality

- Brittle materials can easily be deformed, usually without some tear. This exerts a compressive coupled with a shear force that is mounted on the stock part.

- The formed parts have an excellent surface finish. This minimizes the post-processing machining.

- Metal extrusions produce favorable elongated structures of grains, usually toward the material’s direction.

- As an expert, you can achieve the desired part of the steel

Cold extrusion is one of the most prominent extrusion processes in the metal manufacturing sector. The compressive process involves the deformation of materials. This takes place when a robust pushy punch is used to convert deformation work to heat.

Generally, the pressure is applied to the billet located in the die’s stationery. The pressure applied can happen partially. It may also occur ultimately. But this will be achieved as per the demands of the manufacturer.

Final Thoughts

There are plenty of metal extrusion processes. But manufacturers need to understand what works for them. That way, they can choose the best metal extrusion processes for their procedures. Either way, it all involves pointing out various areas where research should be done.