Traditionally, letterpress printing was a popular method. Its popularity can be attributed to the fact that any substrate could be used with this printing technique. Such substrates include cardboard, cellophane, and metallic film, among others.

This method became the basis for the establishment of novel printing technologies like flexographic printing. Flexographic printing technology is one of the most prevalent printing techniques currently in the market.

What is flexographic printing?

This is a printing technique that involves the use of quick-drying and semiliquid ink. The method also uses rotary in-line elements. The Flexographic printing technique is often referred to as the modern version of letterpress printing. This reference is because this method also allows for the use of a wide range of materials. The most common materials used are paper, cellophane, and plastic, to name a few. It also involves the use of multiple ink colors.

In flexographic printing, elastic photopolymer printing plates are used. These plates are usually enfolded around rotating tubes found on a web press. The plates are also usually inked. To understand this technique better, you need to get how it happens.

The process of Flexographic printing

The process starts with the pre-press phase. This stage is critical because flexographic printing is a high-speed process that requires 100% accuracy. Any inaccuracies stemming from poor preparation can lead to wastage of money by using ink and other materials. Therefore, this phase involves making sure that the printing plate and artwork are prepared correctly. The type of ink is also determined at this stage.

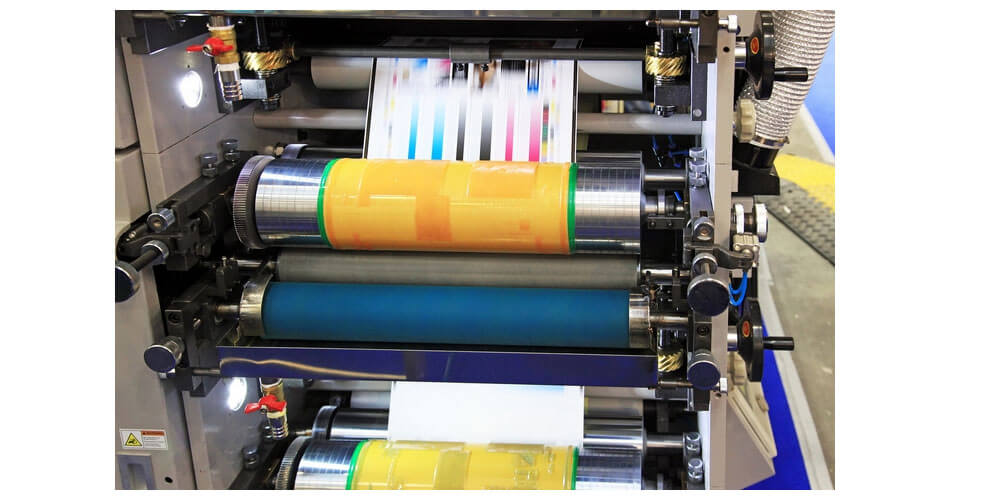

After this stage, the next part of the process is printing. In the flexographic printing model, each press features multiple flexo printing stations. The number of stations depends on the number of colors needed in the process. This means that each station gets to print one of the colors. To achieve this, the substrate has to go through more than one station. At each printing station, a roll of material goes through a flexible rotary plate. Through the rollers, the colors are derived.

The inked flexo printing plates consist of a raised image. As the cylinder rotates at high speed, the image is transferred to the substrate. In this technique, large rolls of materials are used. Doing so allows the printer to run a large order at high speed with the least interruptions.

The history of flexo printing

Flexo printing was introduced in the late 1980s. However, during this time, the process suffered a lot of quality issues. In the early 1990s, many improvements were made to the technology for high-quality printing jobs. The quality-related changes were made to the flexo printing presses, plates, inks, and ink systems.

The printing materials also saw a lot of improvements. These improvements triggered an increased use of the technique over the years.

Conclusion

Flexo printing is often used to fulfill large printing orders. It is popular because of the speed with which it can produce prints and its quality. However, this advantage comes at an increased cost.