Heat sinks are used to cool down components of a processor. They are used to divert heat from the component producing it. They are commonly found in computers and other electrical devices that run consistently. Most mechanical and electronic devices use heat sinks to transfer heat to other components of the device.

These components are super important because they elongate the lifespan of any device. They expel unwanted heat, prevent fires, explosions, injury, and total system failures by absorbing and dispersing internally generated heat. Heat sink extrusion also helps in thermal energy management.

Note that not only devices use heat sinks. Any process that produces heat in large quantities as a by-product needs a heat sink (or related device) to keep the component parts running for the process to complete. It can be a mechanical, nuclear, solar, chemical, or electronic process.

Now, what should you look out for when buying a heat sink?

Heat sink buying guide

1. What type of heat sink do you want to buy?

Several types of heat sinks exist. Your choice of purchase depends on the intended use. Now, there are two types of heat sinks based on the attached cooling components. We have active and passive heat sinks.

What are they?

Active heat sinks are those that require other components like pumps and fans to increase their cooling capacity and hasten heat transfer rate. In most computers and electronic devices, these attached components do not run on the PC’s internally generated power supply.

On the other hand, passive heat sinks do not need additional components to cool a device. By attaching a passive heat sink, they transfer the generated heat through direct contact and the surrounding air.

2. What should the component material be?

¬Heat sinks are made with metals, and the commonest metals are copper and aluminum. A copper heat sink is a preferred choice because it has high thermal conductivity, thereby diverting heat efficiently from the component you want to cool.

However, aluminum is the popular choice. It doesn’t have high thermal conductivity and doesn’t divert heat as well as copper, but companies love producing heat sinks with it because it is less expensive and considerably lightweight compared to copper.

These are very important factors for any company that wants to optimize profit. Aluminum can also be robust when produced in thin sheets, and that’s where extrusion comes in.

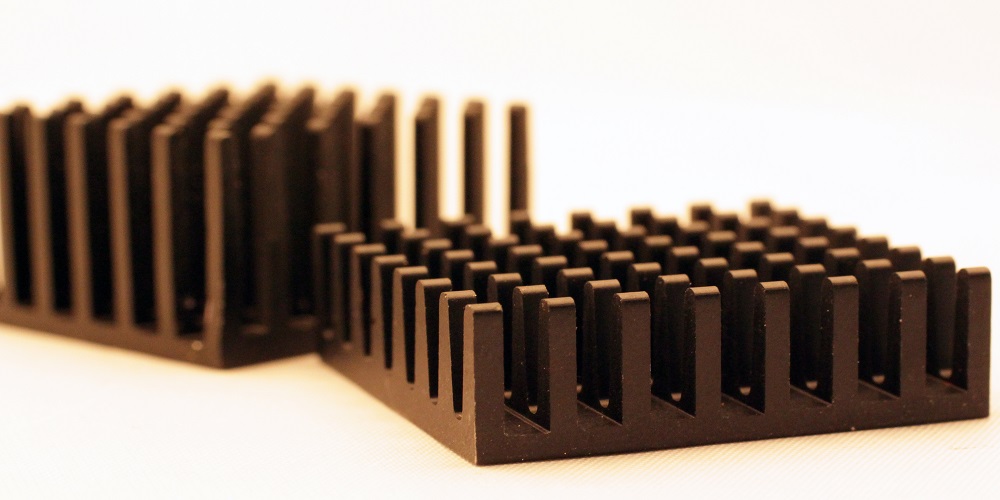

3. Pin or fin?

You should choose between pinned or finned heat sinks.

Finned heat sinks are more popular than pinned heat sinks because they are solid metal blocks that are designed or feathered into several thin plates. This design creates a greater surface area and makes it more efficient for heat transfer. Die-cast finned heat sinks are common because they are cheaper, but CNC milled finned heat sinks are more effective.

Pinned heat sinks are also called pinned fin coolers. It’s almost the same as finned heat sinks, just that the core blocks are made with rods or pins that extend up from the base. The pins can be square or cylindrical.

Although pinned heat sinks have more surface area than finned ones theoretically, they often don’t perform better.